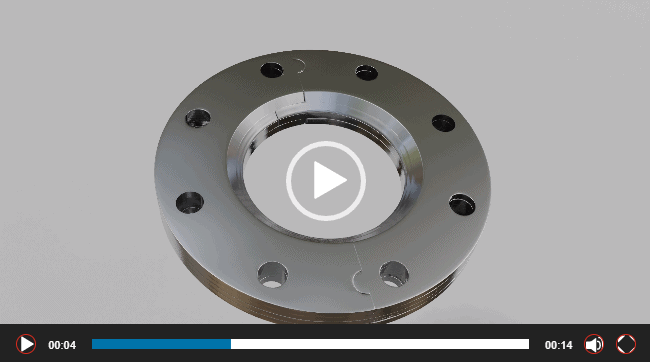

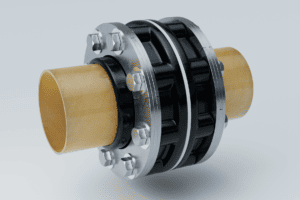

MARZOLF® flanges accommodate most variations of VanStone and lap joint style connections.

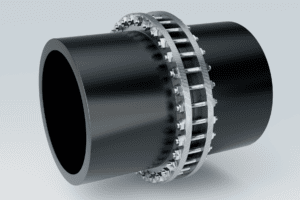

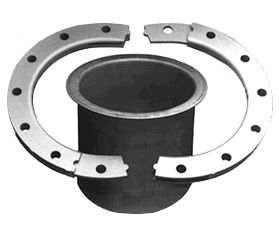

MARZOLF’s unique two-piece flanges interleaving design allows rings to be installed after the stub ends or angle rings have been fused, welded, or glued; to simplify installation. Using MARZOLF split flanges to replace cracked, broken, or corroded VanStone rings is instrumental to getting your facility back online quickly, safely, and cost-effectively.

Our lap joint flanges save you money by, expediting repairs to reduce labor costs, and by minimizing downtime to maximize productivity. Our line of stand-alone rings are used in place of standard one-piece rings on all types of piping including carbon steel, ductile iron, stainless steel, polyethylene, fiberglass, and even PVC and CPVC.

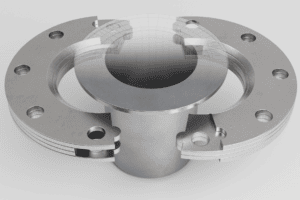

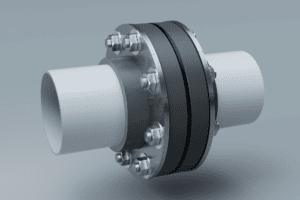

Backing Rings

Our line of backing rings fits behind molded fiberglass flanges and molded PVC and CPVC flanges. These backing rings facilitate higher bolt torques than customarily allowed on molded fiberglass and plastic rings. They also eliminate the cracking which commonly occurs on those types of molded flanges.

If you need a split flange or two-piece backing ring for a particular line in your system, you can rely on us to provide it. If we don’t have the exact item you require, we will custom-manufacture it for you.

Our rings are made of standard materials and non-standard alloys. MARZOLF flanges and backing rings are made to most standard specifications, or configurations, including any national or international standard dimensions. Custom rings can be engineered and produced quickly. Please take the time to browse our catalog for a full range of your most commonly required items.

A combination of Engineered Form and Function MARZOLF flanges are designed, engineered, and manufactured to improve your operations by increasing your productivity and profitability, safely and efficiently.